There are several ways to place a gas vent to the mold, but it can be classified broadly into the following three ways.

・ Gas venting from the divided face of the mold

・ Gas venting from the cavity and core part

・ Gas venting by other special way

1. Gas venting from the divided face of the mold (parting line)

Vent depth should be 0.005mm to 0.02mm, and generally placed on the following location.

+ Preferably far from the gate.

+ Place where weld lines tend to occur.

+ End part of the runner or sub runner.

2. Gas venting from the cavity and core part.

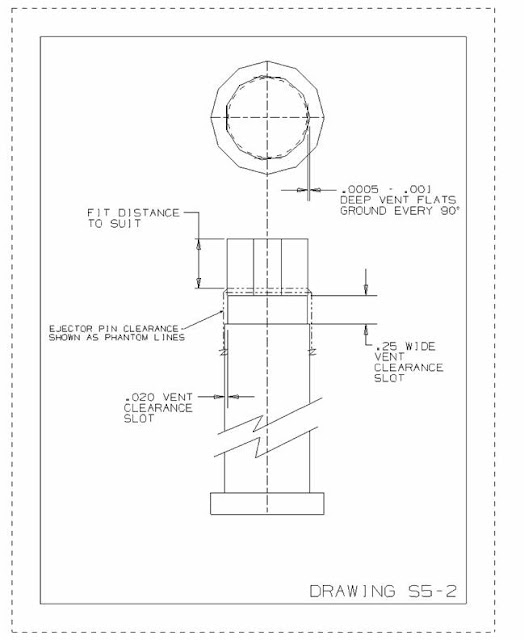

2.1 Using ejector pin

Ejector pin and its hole clearance is used in this method. The clearance of pin and its hole should be

0.02mm to 0.03mm if the pin diameter is about 5mm to 10mm. If it is thinner than this, 0.01mm to 0.02mm

2.2 Using core pin

If there is tall boss or rib on the part of the product, vent by making clearance around the core pin.

|

| gasvent use core pin |

2.3 Layered nesting block.

As a method of gas venting of tall rib, use the clearance made by layered nesting composed of thin

blocks. Also, insert a flat part of the cavity as layered nesting, and vent from the clearance of that thin

3. Gas venting by other special way.

There is a method that ventilates a gas instantaneously by making high-vacuum state inside the

cavity, using the vacuum pump. This method is an ideal as a gas venting method, and also effective

for transfer accuracy upgrading against the mold cavity, but as disadvantage, the cost of equipment

No comments:

Post a Comment