1. Thickness of sample.

If thickness of sample is too thick:

+ it will be the cause of defect: sink mark, short short,...

+ It will take time to cold up and the mold cycle will be longer.

+ To spend much on production is up.

So we try to design thinner thickness .

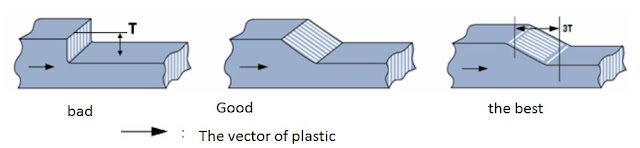

Example for design thickness:

| ||

|

|

| Design of thickness distribution (http://www.m-ep.co.jp) |

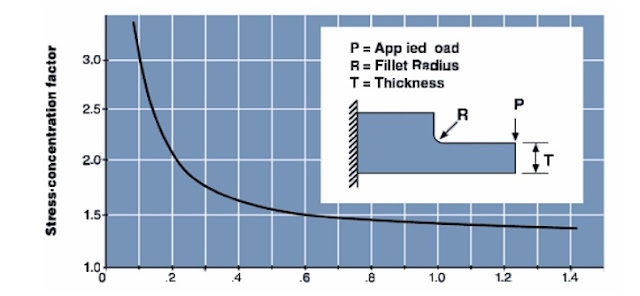

2. Try not to make the sharp corne

|

| make radius |

In this picture: r =( 0.2~0.6)t

Sharp conner will block the resin flow when molding , which will become a cause of flow marks.The stress will concentrate on the sharp corner part.

Result when we make radius for sample:

+ The stress will down

+ The resin flow will better.

+ Warping of product: defect rate of product will down.

+ The molten plastics will insert to mold better.

|

| Corner radius and stress concentration factor |

No comments:

Post a Comment